PERSICO IOT

Persico's MAT

The Industrial IoT solution for the automotive, rotomolding, and nautical sectors.

Client

OCME

Type

OEM

Sector

Packaging

Founded in 1954, OCME is a leading company in the packaging machinery sector. Based in Parma and operating globally, it provides its customers with innovation-based solutions for the packaging of consumer goods. Since 2017, it has been part of the Aetna Group holding, which produces and markets a wide range of machines and lines capable of meeting equally broad production needs, offering tailor-made packaging solutions. OCME, together with Aetna Group, boasts a total turnover of over 350 million euros generated by a team of more than 1,500 professionals working in 9 plants located around the world. Aetna Group is synonymous with great excellence thanks to highly specialized business units, an advanced and exclusive research laboratory system in the world such as TechLab, and above all, a corporate philosophy aimed at consolidating the value of a ONE GLOBAL COMPANY in the market. A synergy of technology, innovation, sustainability, which allows for a comprehensive presence in international markets, offering high-performance solutions tailor-made to the market and customer needs in every corner of the world, with extreme attention to the themes of the circular economy.

It was the innovative character and the forward-looking vision that led OCME to the need for a digital tool that could transform the data generated by its machines into value; features that OCME found in the MAT (Machine Analytics Tool) technology from 40Factory.

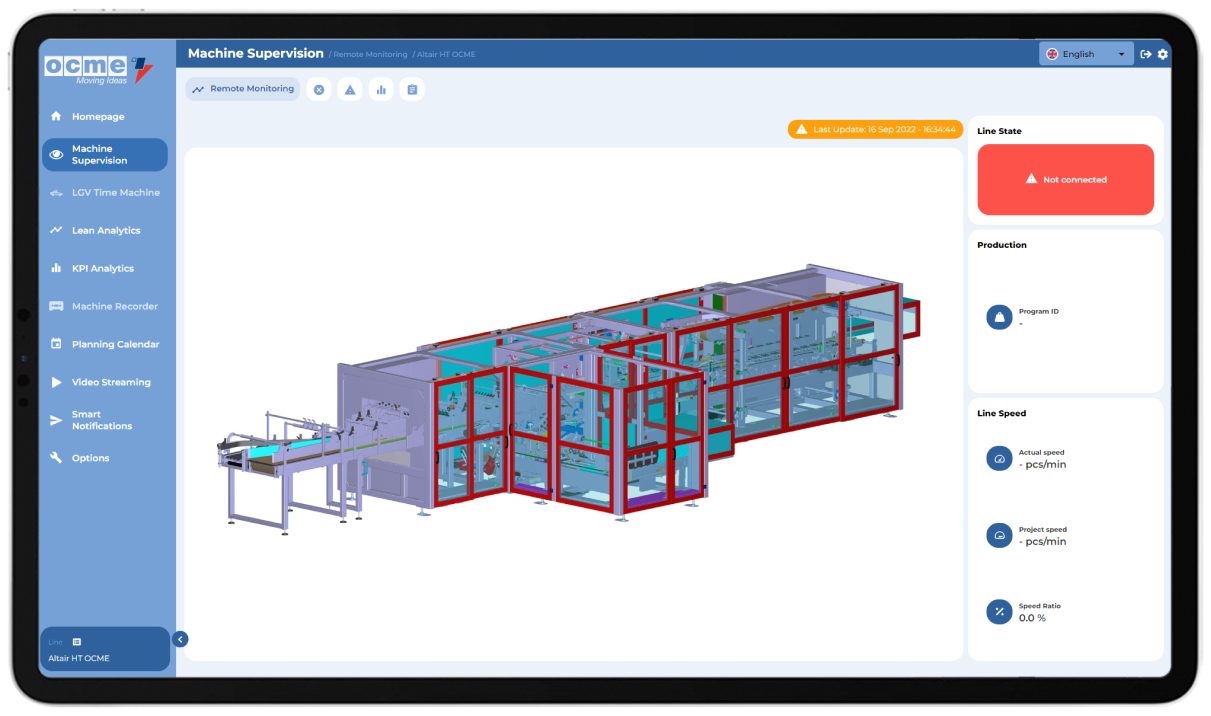

Thus, RDM (Remote Data Monitoring) was born, the Industrial IoT solution for connecting OCME machines and lines; configured with the support of the 40Factory team, it allows managing all essential aspects of the 4.0 packaging line: efficiency analysis, bottleneck identification, quality analysis, process telemetry and black box, energy consumption, preventive and predictive maintenance, and more.

RDM is based on a modular and hybrid Edge & Cloud architecture; raw data, acquired from OCME and third-party machine PLCs, are transformed into smart data by the Edge level and then securely transferred to the Microsoft Azure cloud platform. Here they can be consulted, in a collaborative environment, both by OCME personnel and the end customer.

Using MAT technology, OCME is able to offer its customers a data-driven analysis tool for continuous improvement, as well as being able to offer new value-added services, based on the real knowledge of machine use.