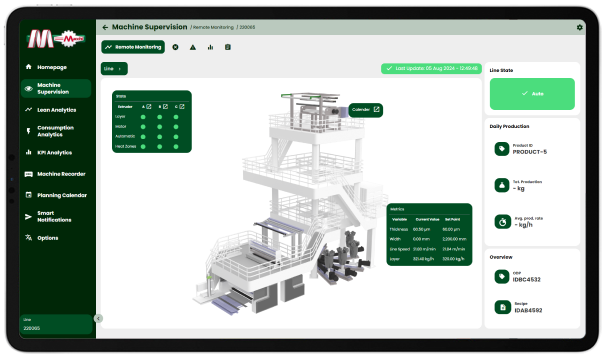

MACCHI IOT

Macchi's MAT

The Industrial IoT solution for traceability and efficiency in production processes in plastic film extrusion plants.

Client

MEP

Type

OEM

Sector

Metal Processing

MEP Group is an internationally prominent industrial company specializing in the design and production of equipment for reinforced concrete rebar processing and welding technology. With a diverse range of machinery, it provides advanced solutions for cutting, shaping, and welding metal, catering to the needs of various industries.

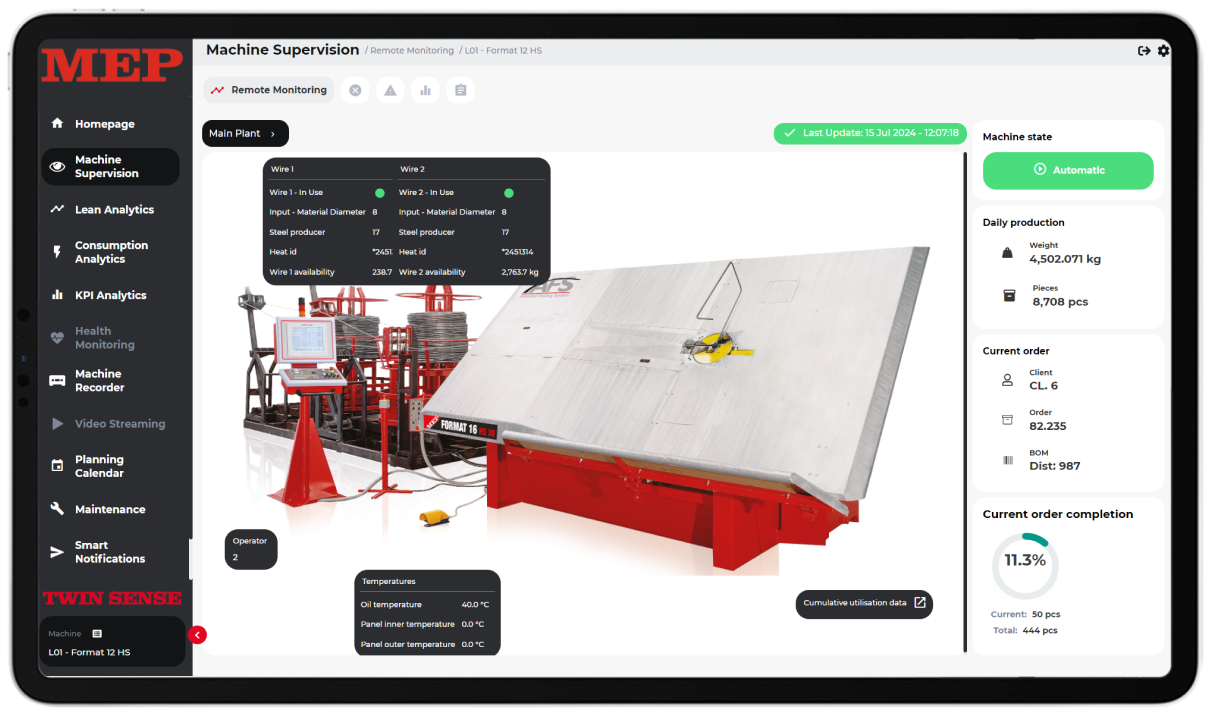

The collaboration with 40Factory began in January 2023 with the goal of transforming data collected from MEP machines into valuable information for monitoring and improving the production quality of their equipment. A unique aspect of this partnership is that the Industrial IoT solution configured for MEP, based on MAT and called “Twin Sense,” does not collect data directly from the PLC using typical automation protocols but receives it through MQTT messages sent from the client’s proprietary software.

For connecting MEP machines, three different data models were created: one for machines with round bar inputs, one for machines with rod inputs, and one for shaping robots. This structure enables MEP to easily connect up to 30 different machine models.

Twin Sense is an edge and cloud solution, depending on the end customer’s preferences. Its configuration focuses on monitoring, analysis, and traceability of production. A practical example of the effectiveness of the production traceability module is its ability to track each production batch associated with a casting ID. This allows for identifying the source of a less performing part, promoting continuous improvement of the production process. Additionally, the fleet KPI functionality enables the comparison of performance across similar machines, answering the question: “Why are some machines in the same family more efficient than others?”

Twin Sense also includes the Maintenance module, which monitors the remaining life of components, allows visualization of which components need to be reordered, generates the bill of materials either manually or automatically, and sends the order to the manufacturer directly with a simple click. Another valuable data provided by the IoT solution is the measurement of scrap: if the waste from a processed bar is shorter than a certain value, it is considered scrap because it is no longer usable, whereas if it is longer, it can be used for further processing. The “smart notifications” feature enables clients to receive real-time alerts on any important events, whether they are telemetric data or KPI reports. This system ensures that users are always up-to-date without the need to constantly check the application.

Thanks to the collaboration with 40Factory and the use of MAT, MEP has implemented a cutting-edge IoT solution, Twin Sense. The application has further reduced the distance with customers, allowing them to focus more on their core business. Meanwhile, MEP ensures increasingly reliable, proactive, and high-quality business continuity.